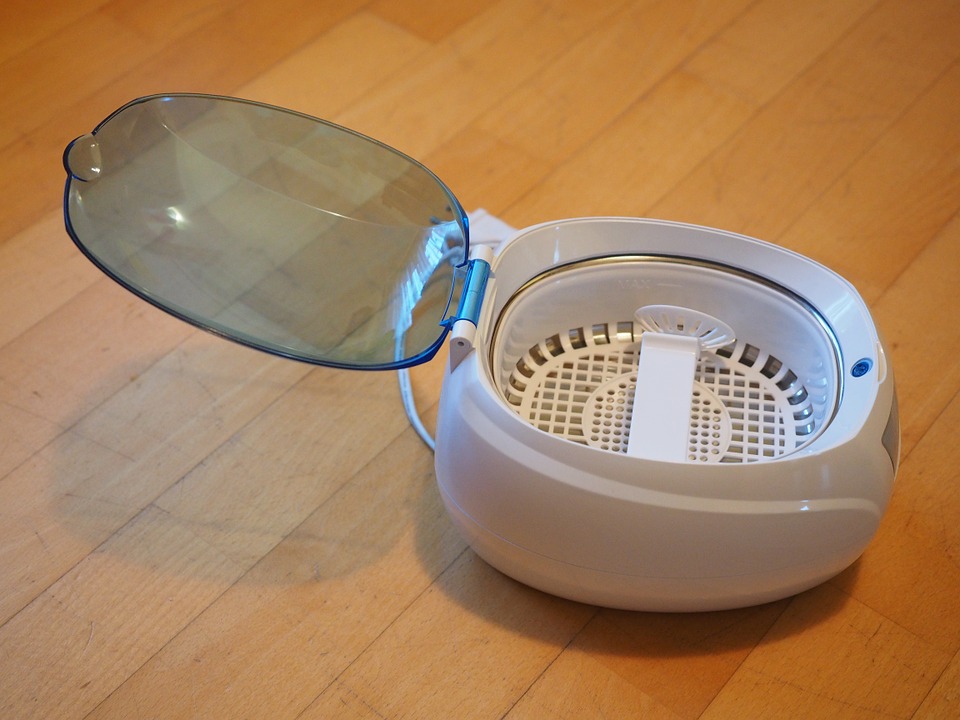

Ultrasonic cleaning is an innovative and effective method of cleaning which is getting a lot of popularity in recent years. The technique uses the scientific process of cavitation for cleaning. The millions of microscopic bubbles created due to cavitation are allowed to implode on the surface of the materials and it removes all the contaminants present on it. Due to its many advantages and its eco-friendly nature, it is one of the most sought out cleaning techniques. It is less time-consuming and uses no harsh chemicals. The ultrasonic cleaning solutions used are biodegradable and not harmful to the people using them. There are many industries that use ultrasonic cleaning for various purposes. Here are some of the best uses of ultrasonic cleaning devices.

Jewelry

Jewelry can contain precious metals or stones. Treating them to chemical cleaners or other mechanical cleaning methods can damage these materials. Ultrasonic cleaners are the ideal technique to clean and restore delicate items like jewelry and watches. The gentle cleaning process is capable of removing dirt, grease, and other contaminants from your valuables without damaging them. It can clean even the tiniest crevices and hidden channels of any jewelry to give clean, shiny, and brand-new-looking ones.

Healthcare

When it comes to healthcare facilities, keeping the instruments clean is not the only challenge. Healthcare professionals and technicians must ensure that all the instruments, implants, and other critical pieces of equipment are both clean and disinfected. Ultrasonic cleaning devices are widely used in healthcare facilities to clean and sanitize at the highest standards. The cleaning process provides the most effective deep cleaning without the use of harsh chemicals that can cause damage to objects or harm the patients involved.

Research labs

Scientific research facilities are another center that requires cleaning and sanitizing. Cleaning glassware types of equipment like test tubes, flasks, cylinders, burettes, and pipettes require careful handling to avoid any breakage. Ultrasonic cleaning makes this task easier and cleans the complex-shaped pieces of equipment efficiently without damaging or breaking them. Solutions with different properties can be used to give more effective results. These properties mainly include the acidic, alkalic or neutral nature of the ultrasonic cleaning solution used.

Restoration

Restoration involves multiple cleaning processes of different components of different characteristics. Mostly done manually to ensure the safety of the delicate items, it is a labor-intensive and time-consuming process. One wrong step can damage the material and destroy it forever. Fortunately, with the help of ultrasonic cleaners, artifacts of any type can be easily cleaned. Specific neutral solutions can be used to prevent any chemical damage and the cavitation process can clean even the deep crevices of each component.

Automotive

Ultrasonic cleaning is used in various sections of the automotive industry. This includes manufacturing, assembly, production, and repair. In each section, the cleaning process involves removing carbon deposits, grease, and other contaminants. It is also used to clean smaller parts like screws, plugs, bolts, and fixtures. One of the main parts that are cleaned used ultrasonic cleaning is the motor. Due to the presence of gentle aluminum parts, these components are cleaned using ultrasonic cleaning to prevent any chance of future corrosion.